Machining

Capabilities

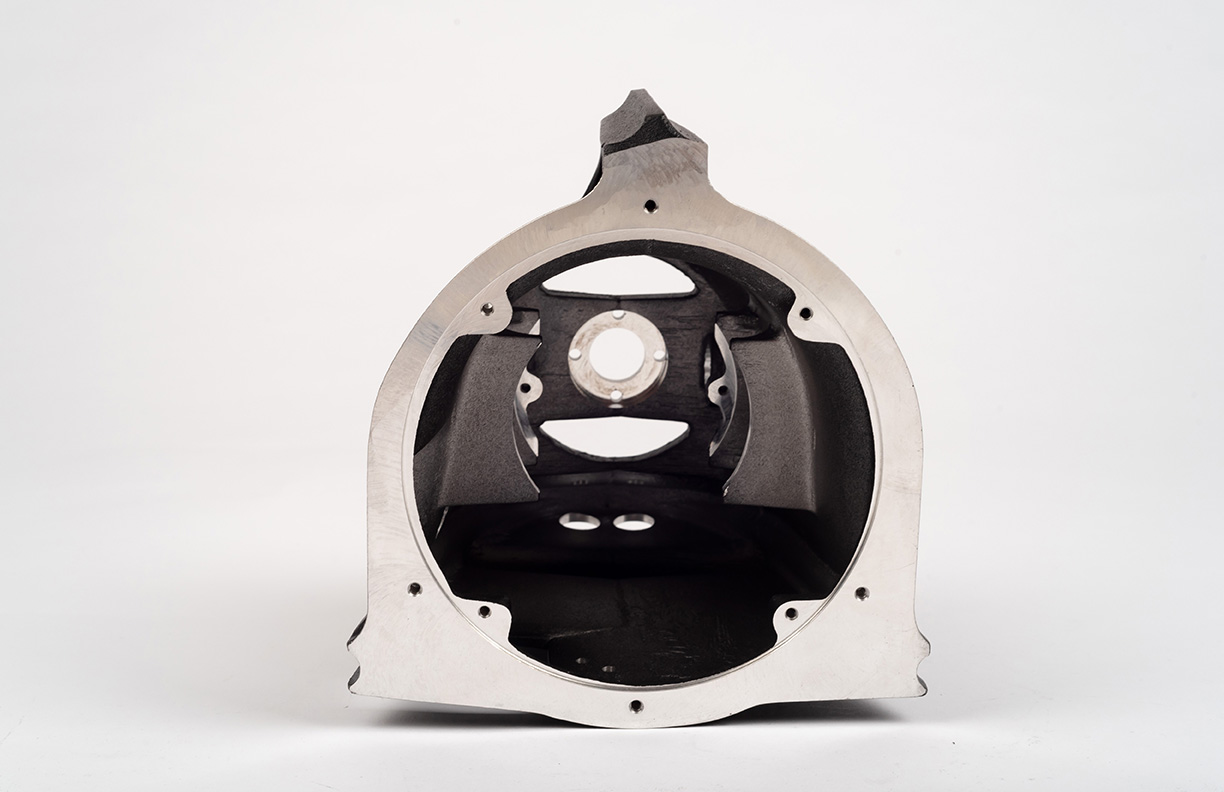

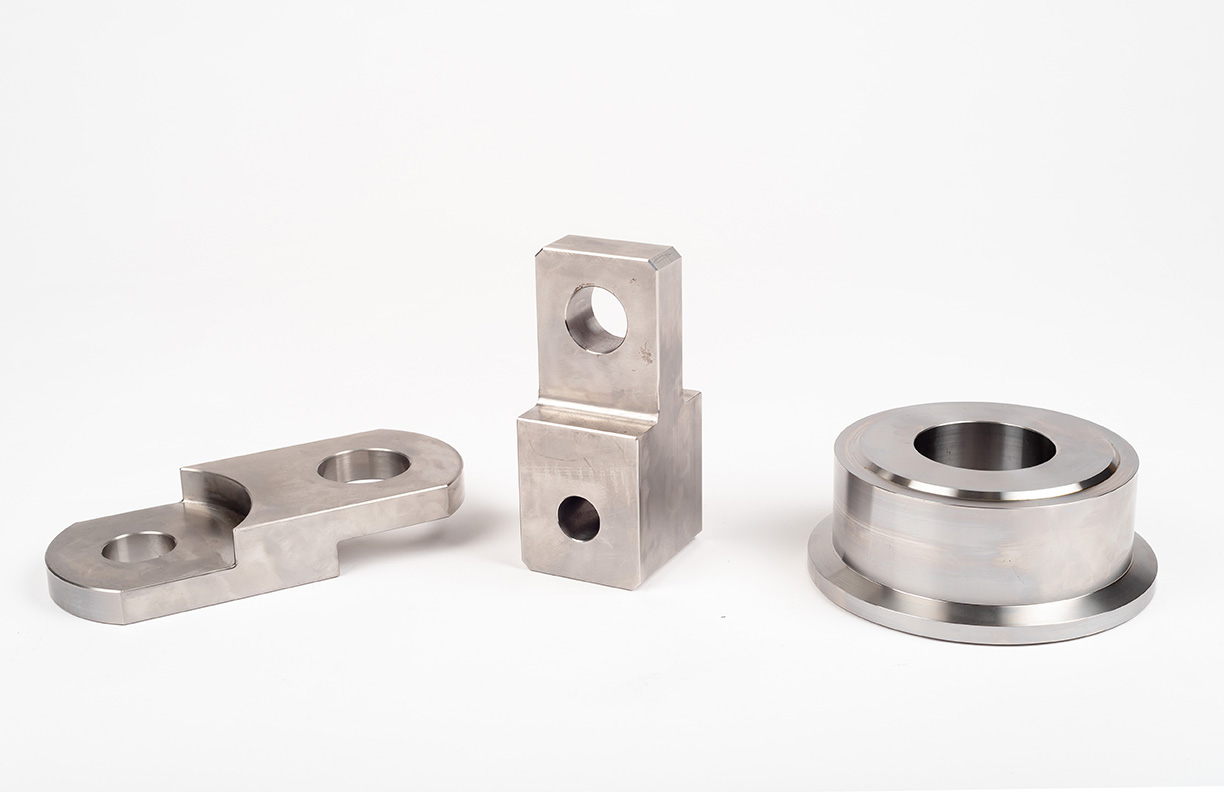

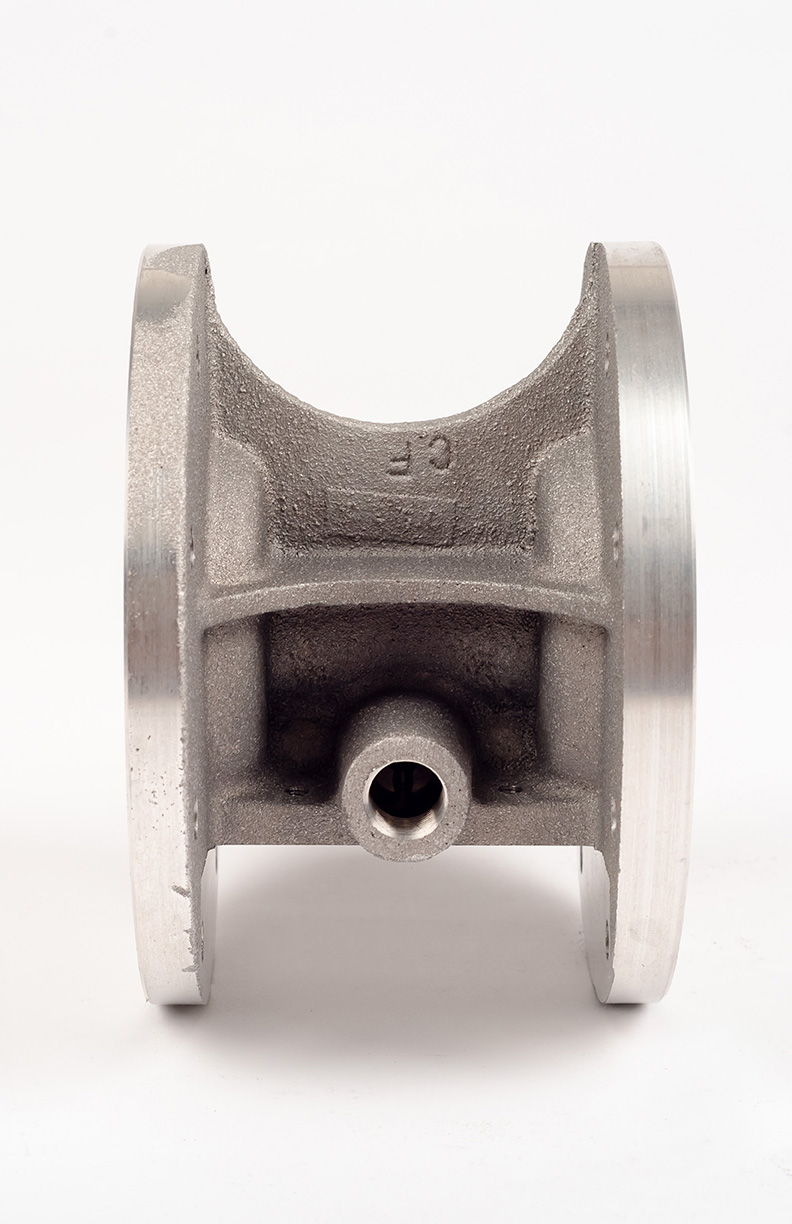

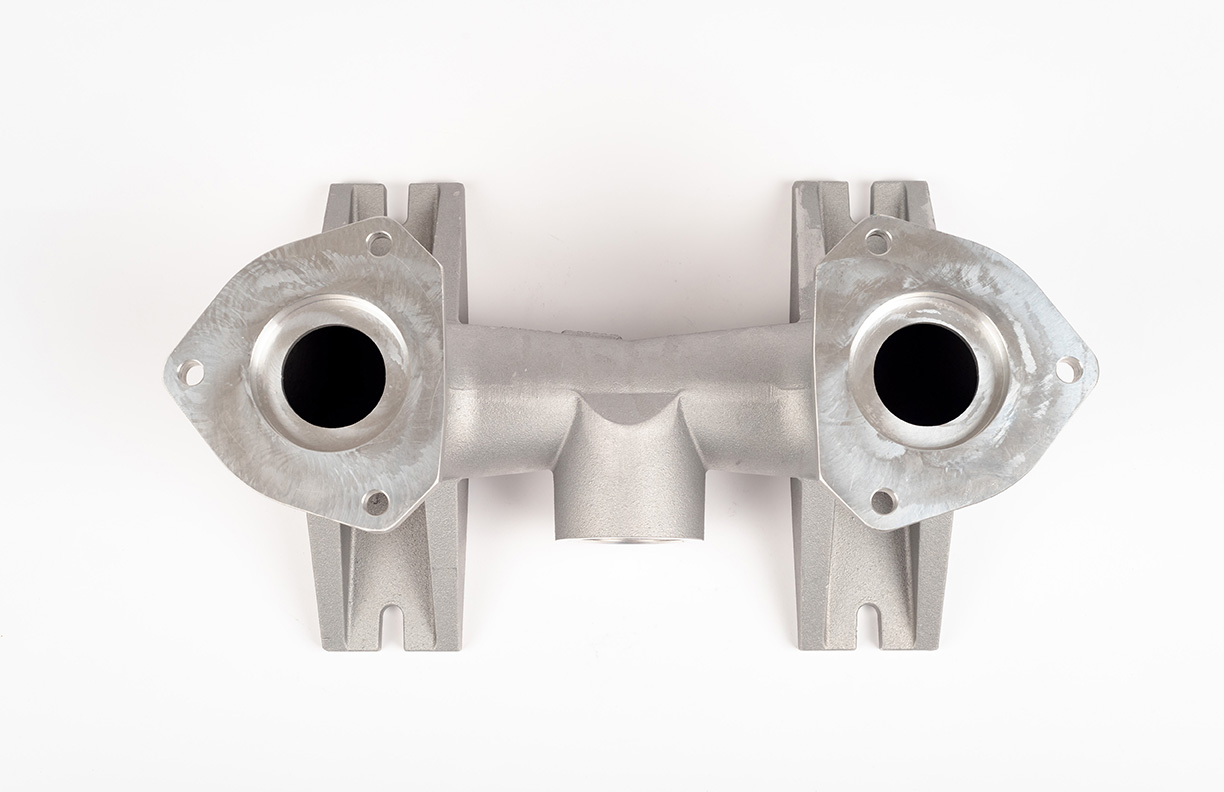

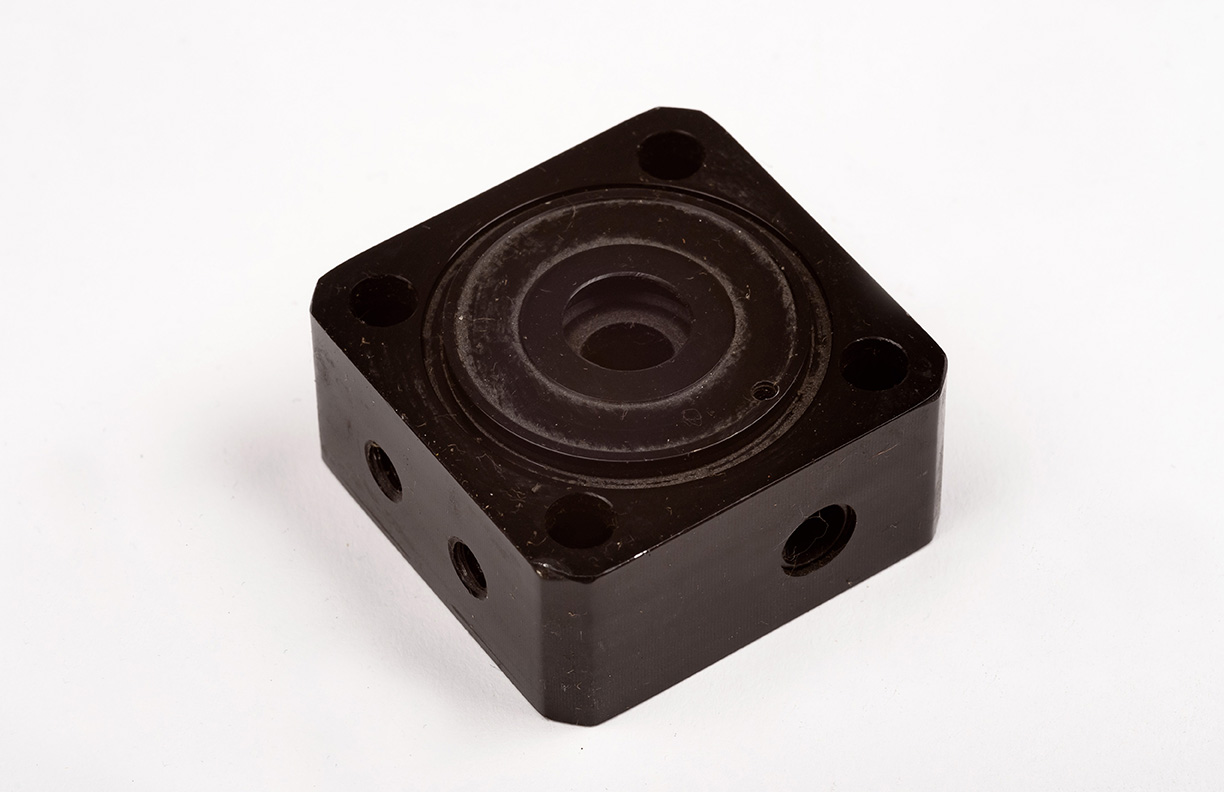

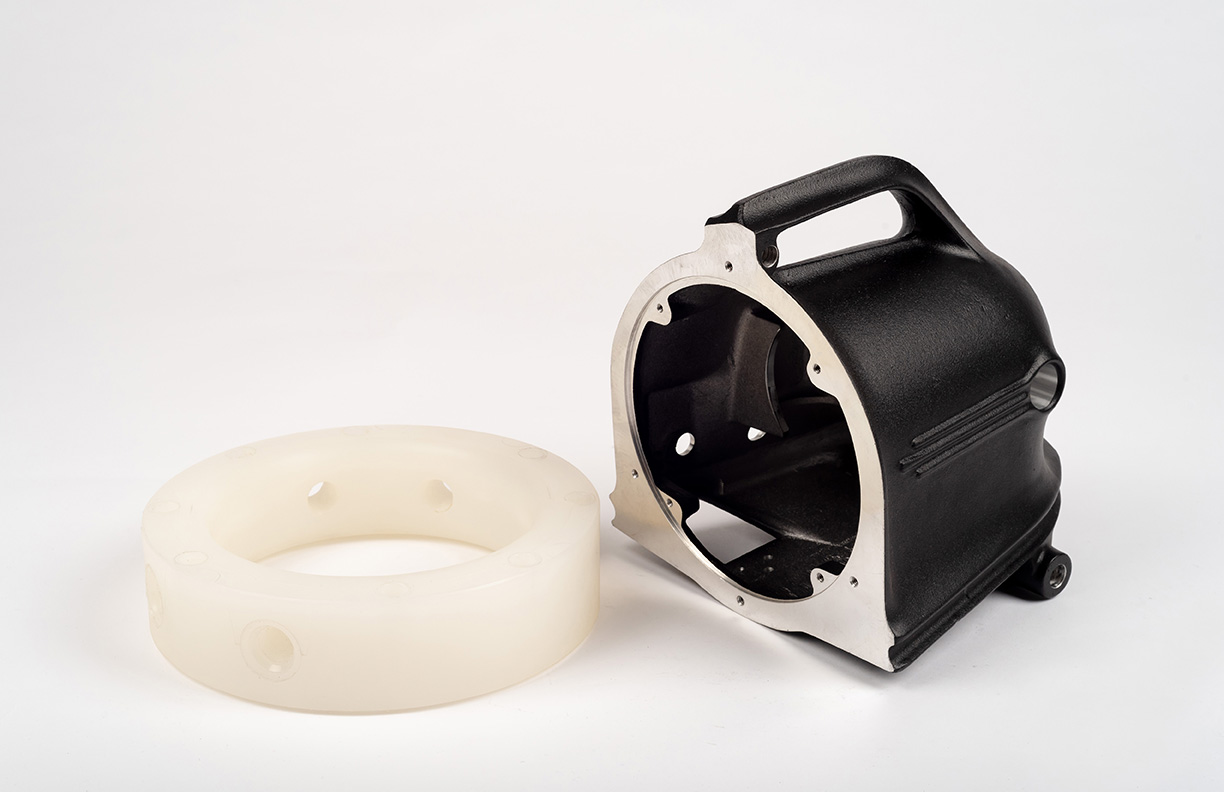

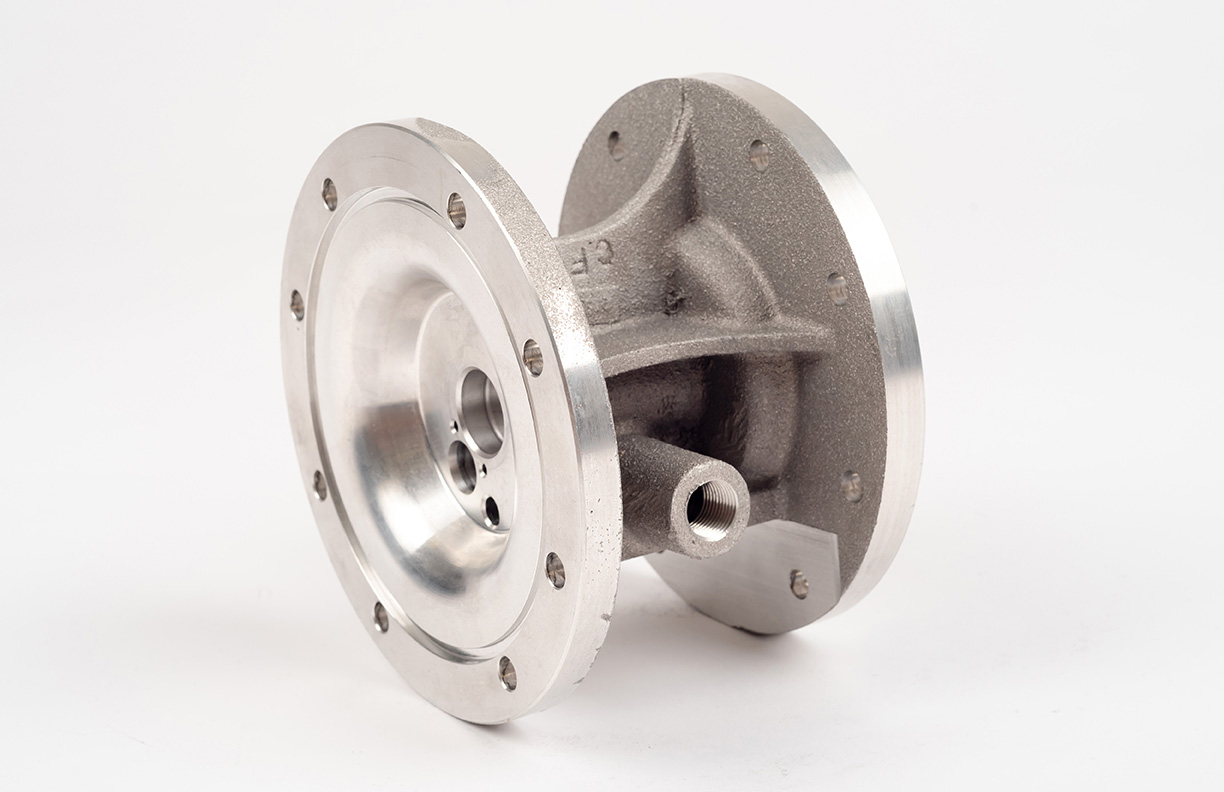

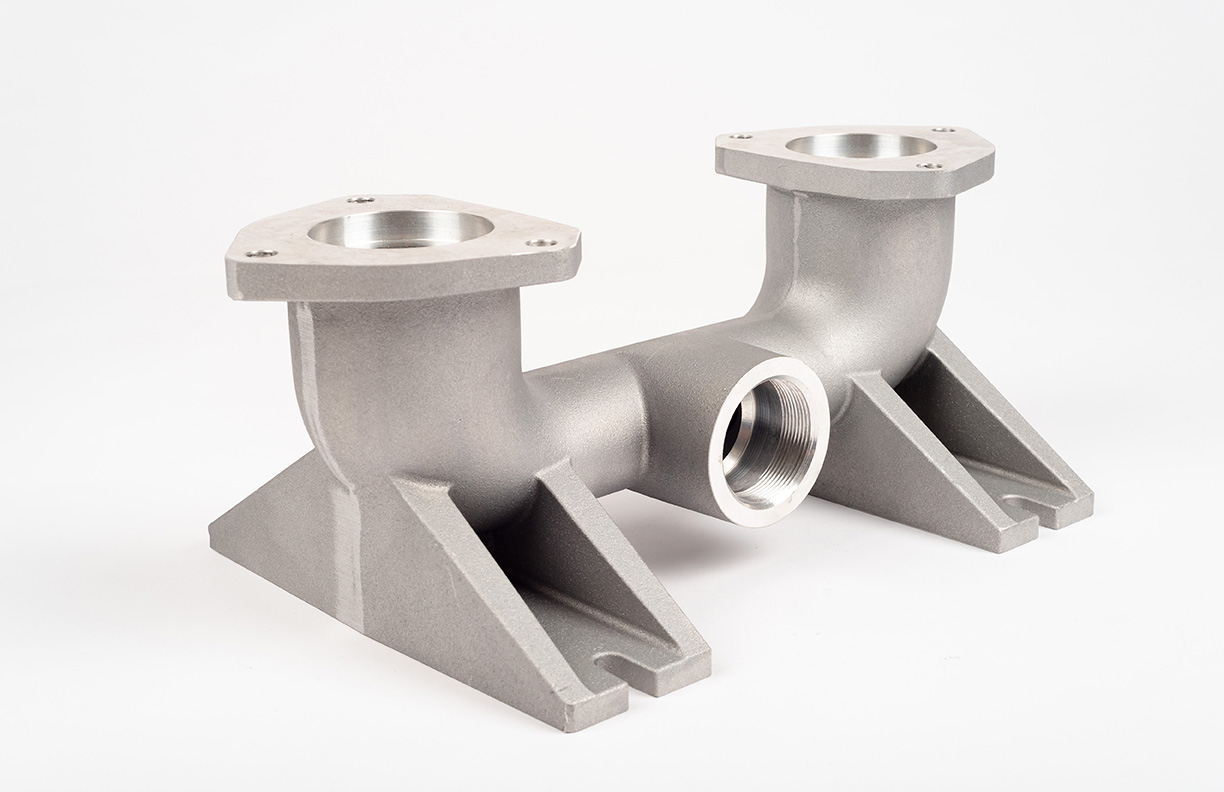

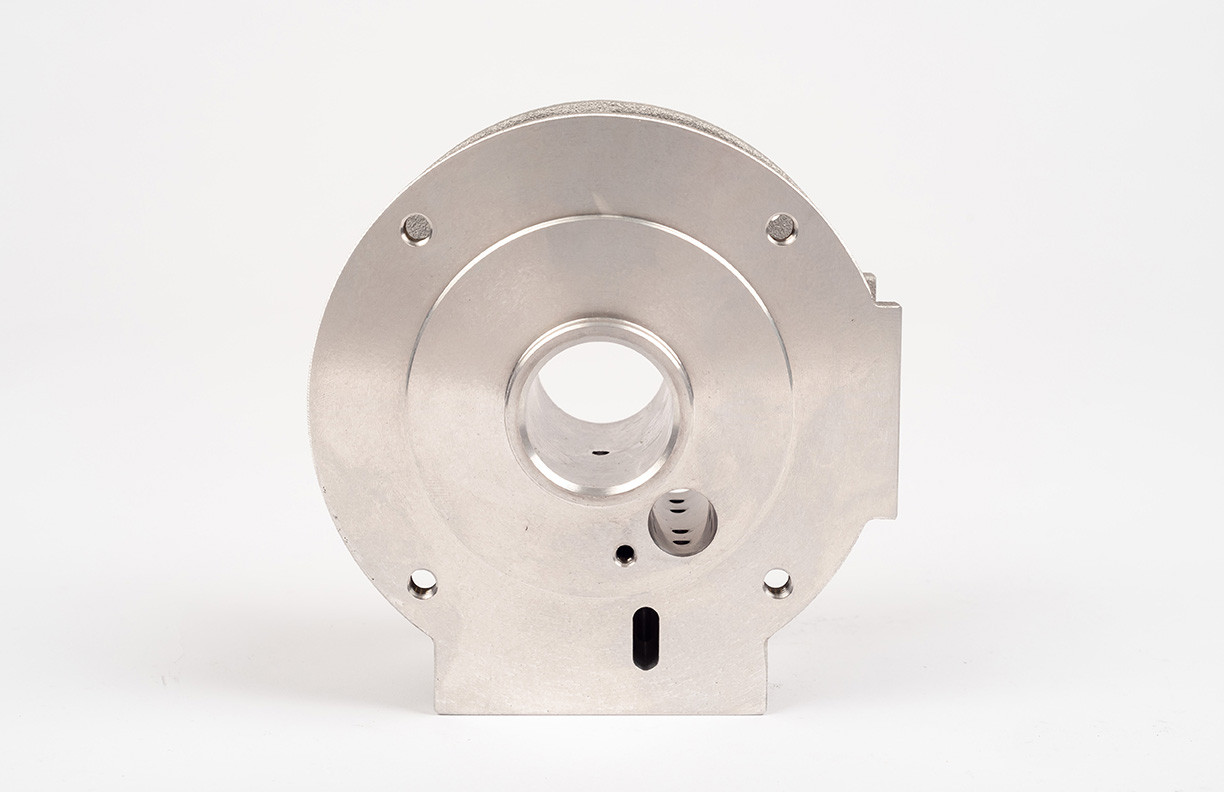

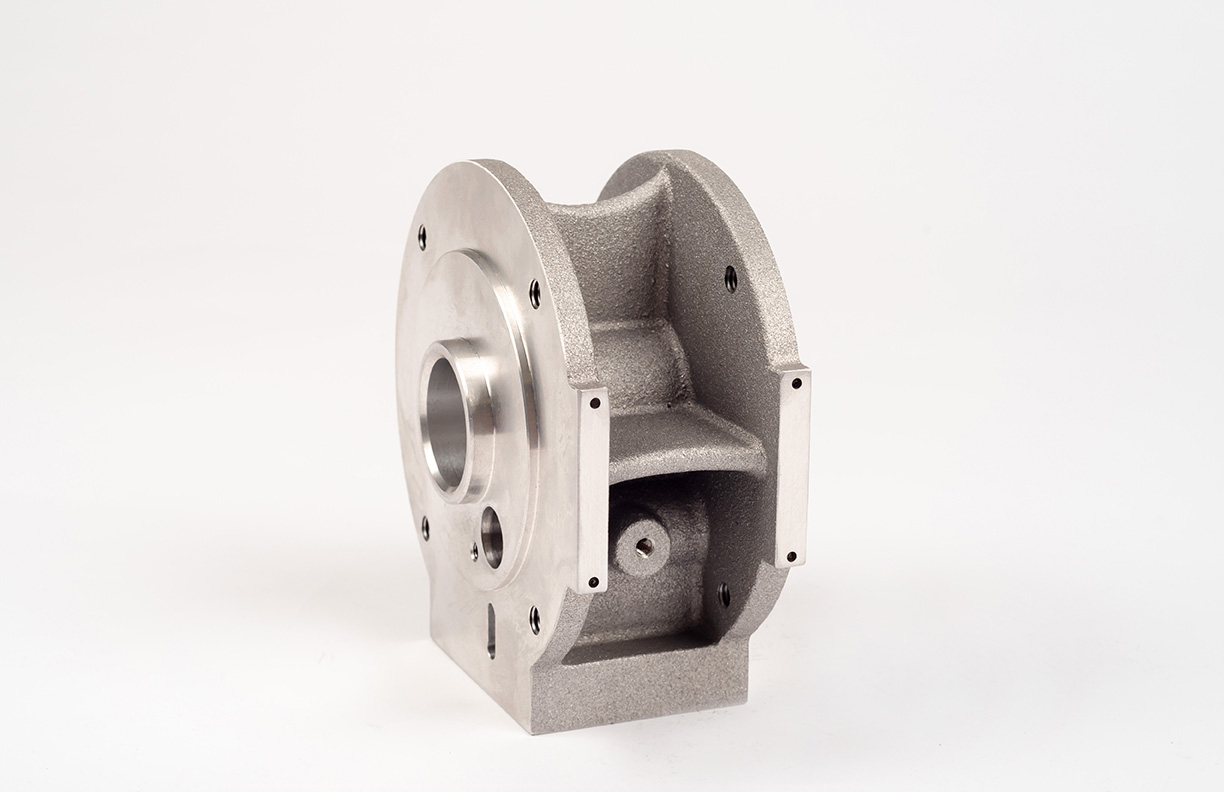

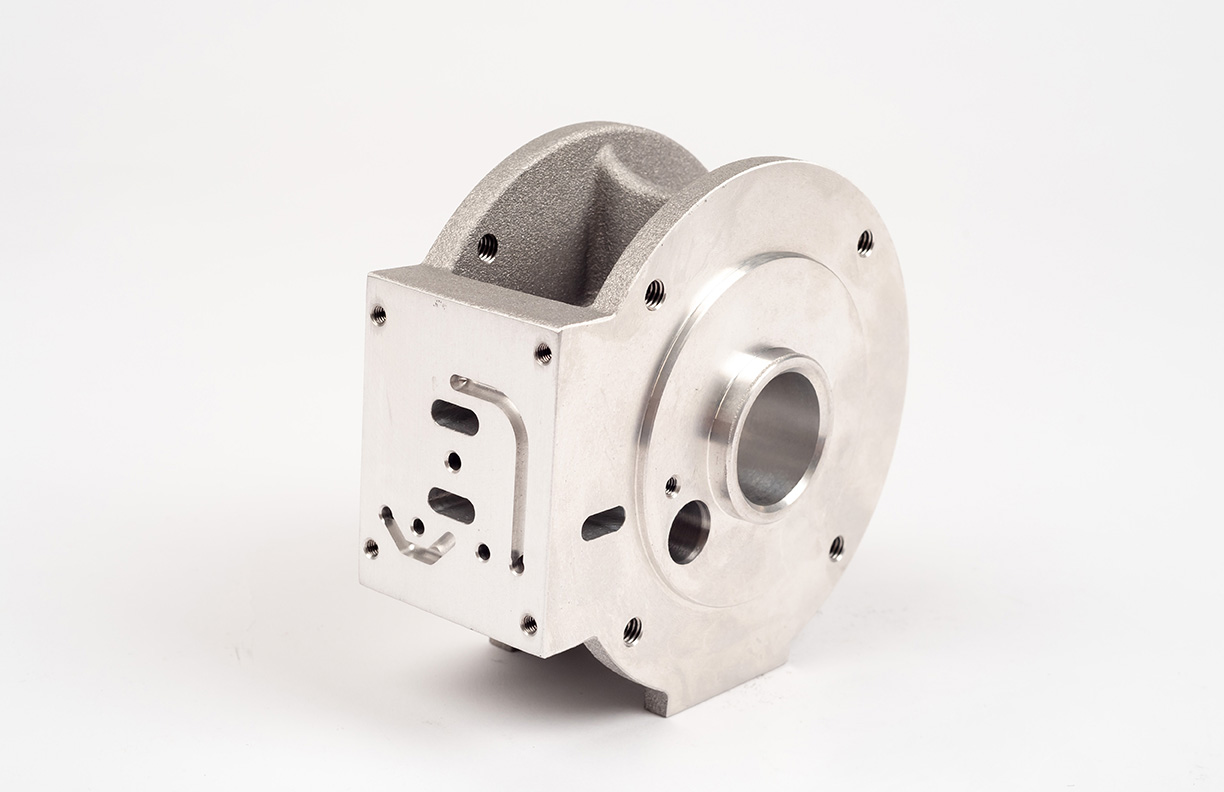

DeMARK will see your project through from design conception to product development. We pride ourselves on our unique ability to make our own products as well as provide contract machining. With the help of our expertise we can reverse engineer your concept to build a workable solid model design of your ideal product. We will provide quality inspection through a variety of tools such as The Faro Arm. Not only is DeMARK a machining company, but we are your single-source partner for CNC machining, centerless grinding, and swiss turn technology.

Click on the image for a larger view

Swiss Style Machining

Citizen M32 Year 2001

CNC Control: Cincom M6B (Mitsubishi)

Axes: X1,Y1,Z1,C1,X2,Z2,C2,X3,Z3

(Misc Axes: T1,A1,A2,A3)

Max. Machining diameter: 1-1/4” (32mm)

Main spindle speeds: 200-8000 rpm

Rotary tool speeds: (turret & gang plate): 250-5000 rpm

Backworking:

Max. Chucking dia: 1-1/4” (32mm)

Max. backwork length: 5.70” (145mm)

Max. Drilling/tapping: M8

Back spindle speeds: 200-7000 rpm

Number of installable tools:

Turret tooling: 10 (20 in half index mode)

Every position on turret has live today capability

Gang- tool tooling:5 turning + rotary=4 Live tools

Back working tool post: 3 (plus rear facing tools on turret)

High pressure Coolant Pump=2000 PSI

LNS 332 Hydro Bar Express Magazine Bar Feeder

Citizen A32/VII Year 2010

CNC Control: Cincom A32 (Mitsubishi)

Axes: X1,Y1,Z1,C1,X2,Z2,C2

Max. Machining diameter: 1-1/4” (32mm)

Max. Machining length per chucking: 12.59” (320mm)

Main spindle speeds: 200-8000 rpm

Rotary tool speeds: (turret & gang plate): 250-5000 rpm

Backworking:

Max. Chucking dia: 1-1/4” (32mm)

Max. backwork length: 5.70” (145mm)

Max. Drilling/tapping: M8

Back spindle speeds: 200-7000 rpm

Number of installable tools:

Gang- tool tooling:5 turning + rotary=4 Live tools

Back working tool post: 3 (plus rear facing tools on turret)

High pressure Coolant Pump=2000 PSI

LNS 332 Hydro Bar Express Magazine Bar Feeder

CNC Machining Centers

1 – Hardinge VMC 600II Year 2002

20 Tool Carousel

Travels X – 23.62 Y –20.16 Z –20.08

Fanuc O Control

1 – Hardinge VMC 600II Year 2006

20 Tool Carousel

Travels X – 23.62 Y – 20.16 Z – 20.08

Thru Spindle Coolant (280 P.S.I.)

Fanuc O Control

1 – Hardinge VMC 600II Year 2005

20 Tool Carousel

Travels X – 23.62 Y – 20.16 Z – 20.08

Thru Spindle Coolant (280 P.S.I.)

Fanuc O Control

1 – Hardinge VMC 600II Year 2005

20 Tool Carousel

Travels X – 23.62 Y – 20.16 Z – 20.08

Thru Spindle Coolant (280 P.S.I.)

Fanuc O Control

1 – Hardinge VMC 600II Year 2006

20 Tool Carousel

Travels X – 23.62 Y – 20.16 Z – 20.08

Thru Spindle Coolant (280 P.S.I.)

Fanuc O Control

1 – Hardinge VMC 600II Year 2006

20 Tool Carousel

Travels X – 23.62 Y – 20.16 Z – 20.08

Thru Spindle Coolant (280 P.S.I.)

Fanuc O Control

1 – Hardinge VMC 800II Year 2005

20 Tool Carousel

Travels X – 31.50 Y – 20.16 Z – 20.08

Thru Spindle Coolant (280 P.S.I.)

Fanuc OI Control

1 – Hardinge VMC 1000II Year 2005

24 Tool Carousel

Travels X – 40.16 Y – 20.16 Z – 20.08

Thru Spindle Coolant (280 P.S.I.)

Two Speed Gear Box

Fanuc OI Control

CNC Turning Centers

Mazak Quick Turn 20 Year 1998

8 Position Turret

10 Chuck

2.0 Diameter Bar Capacity Thru Spindle

16” Swing

17” Between Centers

Mazatrol T + Control

Mazak Quick Turn 20 Year 1997

12 Position Turret

8 Chuck

2.0 Diameter Bar Capacity Thru Spindle

16” Swing

17” Between Centers

Mazatrol + Control

Hardinge 6-45 Talent Year 2006

12 Position turret

3J Collet Nose

Fanuc OI Control

LNS Spacesaver Barfeed

Doosan Dooturn Year 1996

12 Position Turret

12” Chuck

3.5” diameter Bar Capacity Thru Spindle

18” Swing

32” Between Centers

Fanuc 18-T Control

Hardinge GS200 Year 2007

12 Tool Station Turret

8” Chuck

Fanuc OI Control with PC Card Reader

Full C Axis with Live Tool Capability and Parts Catcher

Centerless Grinding

1 – Cincinnati Milacron Year 1993

¼” to 3” Bar / 20” Long

1 – Barnes Magnetic Fabric Filter

Saw Cutting

1 – Kalamazoo: KC12AX Year 2010

10” Max. Rd. Sq. Rect.

Indexers

6 – Yuasa 220 SUDX CNC Driven Indexers

1 – Yuasa Manual Indexer

Broach

2 – Lapointe 36” Horzontal pull style

Cad Cam Software

Partmaker software for Swiss Turn, Turn Mill, Mill

WINCNC Swiss Software

Autocadd Lt 2000

1- CNC XR5

Rhinoceros (NURBS modeling for windows)

Solidworks 2012

Designworks

Bar Machines

2 – Davenport 5 Spindle Automatic Screw Machines

Pick Off and Back Burr ability

Universal Threading

2 – 1” RA6 Acme

Universal Threading

Accelerated reaming

2 – 1 ¼ RA-6 Acme

Unversal Threading

Accelerated reaming

1 – 5/8 RA-6 Acme

2 – 2 5/8 RA-6 Acme

Universal Threading

Accelerated Reaming

1 – 1 5/8 RA-4 Acme

1 – 2” RA-4 Acme